The Complete Guide to External Wall Insulation and Rendering

Share

External wall insulation (EWI) combined with rendering represents one of the most effective solutions for improving a building's thermal performance while simultaneously enhancing its aesthetic appeal. This comprehensive guide explores everything you need to know about external wall insulation and rendering systems, from their fundamental benefits to installation processes and long-term value.

Understanding External Wall Insulation

External wall insulation involves applying insulation material to the exterior walls of the building, followed by a protective render or cladding finish. This integrated approach creates a thermal envelope around the structure, dramatically reducing heat loss through the walls while providing a fresh, contemporary appearance.

Unlike internal insulation, which reduces interior space and can disrupt occupants during installation, external insulation offers a non-intrusive solution that maintains internal living areas while the building remains fully functional throughout the installation process. This makes EWI particularly suitable for occupied properties where minimizing disruption is essential.

The concept of external wall insulation has evolved significantly over recent decades, with modern systems offering unprecedented thermal performance, durability, and design flexibility. Today's EWI solutions incorporate advanced materials and installation techniques that address the complex demands of energy efficiency, weather resistance, and architectural aesthetics.

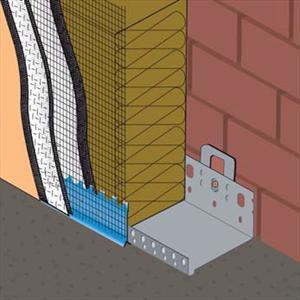

At its core, an external wall insulation system consists of several key components working together to create a thermally efficient and weather-resistant envelope. These components typically include insulation boards, mechanical fixings, base coat, reinforcement mesh, and a decorative finish coat or render. Each element plays a vital role in the system's overall performance and longevity.

The Compelling Benefits of External Wall Insulation

The decision to invest in external wall insulation delivers multiple advantages that extend far beyond simple energy savings. Understanding these comprehensive benefits helps property owners and professionals appreciate the full value proposition of EWI systems.

Significant Energy Efficiency Improvements

Perhaps the most compelling advantage of external wall insulation is its remarkable impact on energy efficiency. Uninsulated solid walls can lose up to 45% of a building's heat, making them a primary source of energy waste in older properties. By creating a continuous thermal barrier, EWI dramatically reduces this heat loss, with typical U-value improvements from 2.1 W/m²K for an uninsulated solid wall to 0.3 W/m²K or better after installation.

This substantial improvement in thermal performance translates directly to reduced energy consumption for heating. Most properties experience heating cost reductions of 25-35% following EWI installation, representing significant financial savings over the system's lifetime. For a typical three-bedroom semi-detached house, this can amount to £300-£500 in annual savings on heating bills.

Beyond the immediate financial benefits, the reduced energy consumption contributes to lower carbon emissions, helping property owners reduce their environmental footprint. For a typical installation, carbon dioxide emissions can be reduced by 1.5-2 tonnes annually, making EWI a meaningful contribution to climate change mitigation efforts.

Enhanced Comfort and Living Conditions

The thermal benefits of external wall insulation extend beyond energy savings to create noticeably improved living conditions within the property. The insulation layer stabilizes internal temperatures, reducing the dramatic fluctuations that often occur in poorly insulated buildings.

During winter months, the insulation retains heat within the structure, eliminating the cold spots and drafts commonly experienced near external walls in uninsulated properties. This creates a more consistent, comfortable environment throughout the building and reduces the need for supplementary heating in previously problematic areas.

In summer, the insulation layer helps prevent heat gain, keeping interior spaces cooler during hot weather. This dual-season benefit ensures year-round comfort with minimal energy input, reducing reliance on both heating and cooling systems.

The improved thermal performance also raises the temperature of internal wall surfaces, reducing the risk of condensation that can lead to damp and mold problems. Many property owners report significant improvements in indoor air quality following EWI installation, with reduced instances of respiratory issues and allergic reactions among occupants.

Property Protection and Weather Resistance

Beyond thermal benefits, external wall insulation provides exceptional protection for the building structure. The combination of insulation and render creates a weather-resistant shield that protects the underlying construction from rain, frost, and UV damage.

For older properties with solid brick or stone walls, this protective layer prevents moisture penetration that can lead to damp issues internally. The breathable nature of modern EWI systems allows any trapped moisture to escape while preventing new moisture from entering, creating a balanced environment that preserves the building fabric.

The protective benefits are particularly valuable in exposed or coastal locations, where driving rain and harsh weather conditions can accelerate the deterioration of traditional building materials. The resilient outer render layer stands up to these challenging conditions, extending the lifespan of the underlying structure and reducing maintenance requirements.

Freeze-thaw cycles, which can cause significant damage to masonry over time, have minimal impact on properly installed EWI systems. The insulation layer maintains the wall structure at a more stable temperature, reducing the expansion and contraction that leads to cracking and spalling in unprotected walls.

Aesthetic Transformation and Value Enhancement

One of the most immediately apparent benefits of external wall insulation is the dramatic aesthetic improvement it delivers. The render finish creates a fresh, contemporary appearance that can completely transform dated or deteriorated façades.

Modern render systems are available in an extensive range of colors and textures, allowing property owners to achieve their desired aesthetic while maintaining harmony with surrounding buildings. From traditional sand and cement finishes to contemporary silicone renders with enhanced performance characteristics, the design possibilities are virtually limitless.

For properties with mixed façades or unsightly repairs, EWI creates a uniform appearance that enhances curb appeal and makes a positive first impression. This aesthetic improvement often translates to increased property value, with studies suggesting that well-executed external insulation and rendering can add 5-8% to a property's market value.

The visual transformation extends beyond simple aesthetics to create a perception of quality and care that influences potential buyers' or tenants' impressions of the property. This "pride factor" can be particularly valuable in competitive property markets where distinctive, well-maintained exteriors command premium prices.

Noise Reduction and Acoustic Benefits

An often-overlooked advantage of external wall insulation is its contribution to improved acoustic performance. The insulation layer absorbs and dampens sound vibrations, reducing the transmission of external noise into the building.

This acoustic benefit is particularly valuable for properties in urban environments or near transportation routes, where traffic noise can significantly impact quality of life. The reduction in noise transmission creates a quieter, more peaceful internal environment that enhances occupant comfort and wellbeing.

The acoustic improvements work in both directions, also reducing the transmission of internal noise to the outside environment. This can be particularly beneficial for properties where privacy is important or where internal activities might otherwise disturb neighbors.

Depending on the specific insulation material and system thickness, noise reduction of 5-10 decibels can be achieved, representing a significant improvement in acoustic comfort. This translates to a perceived noise reduction of up to 50%, dramatically enhancing the living experience within the property.

Types of Insulation Materials for External Wall Systems

Selecting the appropriate insulation material is crucial for achieving optimal performance in an external wall insulation system. Each material offers distinct characteristics that make it suitable for specific applications and requirements.

Expanded Polystyrene (EPS)

Expanded Polystyrene represents the most widely used insulation material for external wall systems, accounting for approximately 70% of installations in the UK. This popularity stems from its excellent balance of performance, cost-effectiveness, and ease of installation.

EPS is manufactured by expanding polystyrene beads using steam, creating a closed-cell structure that traps air to provide insulation. The resulting material offers a thermal conductivity typically ranging from 0.032 to 0.038 W/mK, delivering effective thermal performance at a competitive price point.

Beyond its thermal properties, EPS offers several practical advantages for external wall applications. The material is lightweight, making it easy to handle and install, reducing labor costs and installation time. It can be easily cut and shaped on-site to accommodate architectural features and ensure a precise fit around windows, doors, and other details.

EPS demonstrates good dimensional stability, maintaining its shape and size over time without significant shrinkage or expansion that could compromise the render system. It also offers reasonable vapor permeability, allowing the wall structure to breathe while providing the necessary thermal barrier.

From an environmental perspective, EPS has improved significantly in recent years. Modern EPS products often incorporate recycled content and are themselves fully recyclable at the end of their service life. The manufacturing process has also become more energy-efficient, reducing the material's overall environmental footprint.

The typical lifespan of EPS in external wall applications exceeds 60 years when properly installed and protected by appropriate render systems. This longevity, combined with its competitive cost (typically £8-12 per square meter for 100mm thickness), makes EPS a cost-effective choice for many projects.

Mineral Wool

Mineral wool insulation, derived from rock (stone wool) or slag (slag wool), offers a combination of thermal and acoustic performance with exceptional fire resistance properties. These characteristics make it particularly suitable for high-rise buildings and applications where fire safety is a primary concern.

The manufacturing process involves melting rock or slag and spinning it into fibers, creating a material with a thermal conductivity typically ranging from 0.034 to 0.040 W/mK. While slightly less thermally efficient than some alternatives, mineral wool compensates with superior fire performance, achieving a Euroclass A1 (non-combustible) fire rating.

The fibrous structure of mineral wool provides excellent acoustic properties, absorbing sound waves more effectively than closed-cell insulation materials. This makes it an ideal choice for properties in noisy environments or where sound transmission is a concern.

Mineral wool's vapor-open structure creates a highly breathable insulation layer that facilitates the movement of moisture through the wall assembly. This breathability makes it particularly suitable for traditional buildings where maintaining the wall's ability to manage moisture is essential for preserving the building fabric.

The material demonstrates good dimensional stability and resistance to aging, maintaining its performance characteristics throughout its service life. It is also resistant to vermin and will not provide a food source for insects or rodents, an important consideration for long-term installation integrity.

From an environmental standpoint, mineral wool offers several advantages. It typically contains 30-60% recycled content and is fully recyclable at the end of its life cycle. The raw materials used in its production are abundant natural resources, making it a sustainable choice for environmentally conscious projects.

The higher cost of mineral wool (typically £12-18 per square meter for 100mm thickness) is often justified by its superior fire performance and acoustic benefits, particularly in multi-residential or commercial applications where these factors are critical considerations.

Phenolic Foam

Phenolic foam represents the premium end of the insulation spectrum, offering exceptional thermal performance that makes it ideal for projects where space is limited or where maximum energy efficiency is required.

This advanced insulation material is manufactured using phenolic resin with added blowing agents and surfactants, creating a closed-cell structure with thermal conductivity as low as 0.020-0.023 W/mK. This outstanding thermal efficiency allows phenolic foam to achieve the same insulation value with significantly less thickness compared to other materials.

The space-saving advantage of phenolic foam makes it particularly valuable in urban environments where boundary constraints might limit the projection of external wall insulation. A typical phenolic system can achieve a U-value of 0.28 W/m²K with just 60-70mm thickness, compared to 100mm or more required with alternative materials.

Phenolic foam offers excellent fire performance, typically achieving a Euroclass B or C rating depending on the specific formulation. While not non-combustible like mineral wool, it demonstrates low flame spread and heat release characteristics that make it suitable for many high-performance applications.

The material exhibits good dimensional stability and resistance to moisture absorption, maintaining its performance characteristics even in challenging environmental conditions. It is also resistant to most common chemicals and will not deteriorate when exposed to typical construction materials.

The premium performance of phenolic foam comes with a higher cost (typically £18-25 per square meter for 60mm thickness), making it most appropriate for projects where space constraints or exceptional thermal performance justify the additional investment.

Expanded Cork

For projects prioritizing natural, sustainable materials, expanded cork offers a compelling alternative to synthetic insulation options. Derived from the bark of cork oak trees, this renewable material provides good thermal performance with exceptional environmental credentials.

Expanded cork is produced by subjecting cork granules to superheated steam, causing the natural resins within the material to expand and bind the granules together without additional adhesives. This process creates a material with thermal conductivity typically ranging from 0.040 to 0.045 W/mK.

While not matching the thermal efficiency of synthetic alternatives, expanded cork offers several unique advantages. The material provides excellent acoustic performance, absorbing sound waves effectively due to its cellular structure. It also demonstrates good thermal mass properties, helping to stabilize internal temperatures by absorbing and releasing heat gradually.

Cork's natural resistance to moisture, fungi, and insects makes it durable in external applications without requiring chemical treatments. It maintains its dimensional stability and performance characteristics thro